As an experienced IELTS instructor, I’m excited to share a comprehensive IELTS Reading practice test focusing on the topic of “How automation is improving product quality.” This test will help you familiarize yourself with the IELTS Reading format while exploring an important technological trend. Let’s dive in!

Introduction

The IELTS Reading test assesses your ability to understand and analyze complex texts. Today, we’ll practice with passages related to automation and its impact on product quality. This topic is not only relevant for the IELTS exam but also crucial for understanding modern manufacturing processes.

IELTS Reading Test: Automation and Product Quality

Passage 1 – Easy Text

The Rise of Automation in Manufacturing

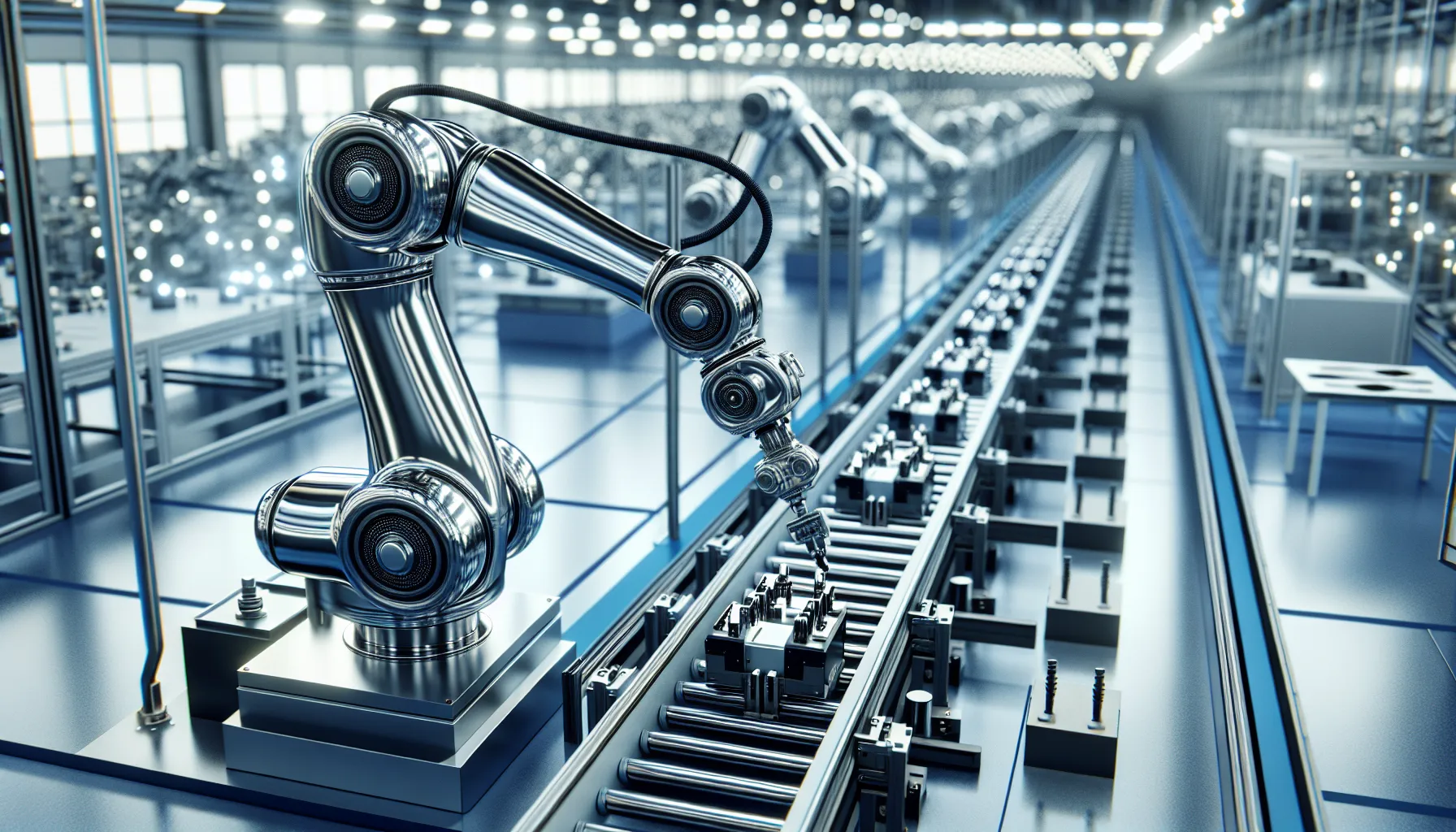

Automation has become an integral part of modern manufacturing processes. From assembly lines to quality control, machines and robots are increasingly taking over tasks once performed by human workers. This shift towards automation has brought about significant changes in how products are made and inspected.

One of the primary benefits of automation is its ability to improve product quality. Automated systems can perform repetitive tasks with a high degree of precision and consistency, reducing the likelihood of human error. For example, in the automotive industry, robots are used to weld car bodies together with remarkable accuracy, ensuring that each vehicle meets strict quality standards.

Moreover, automation has enhanced the efficiency of production processes. Machines can work tirelessly around the clock, increasing output without compromising on quality. This increased productivity allows companies to meet growing consumer demands while maintaining high standards of quality control.

Another advantage of automation is its capacity for data collection and analysis. Automated systems can gather vast amounts of data about the production process, enabling manufacturers to identify and address quality issues quickly. This real-time monitoring and feedback loop contribute to continuous improvement in product quality.

However, the implementation of automation is not without challenges. Initial costs can be substantial, and there is often a need for specialized training for employees who will operate and maintain the automated systems. Additionally, there are concerns about job displacement as machines take over tasks previously performed by human workers.

Despite these challenges, the trend towards automation in manufacturing continues to grow. As technology advances, we can expect to see even more sophisticated automated systems that further enhance product quality and revolutionize the manufacturing industry.

Questions 1-5

Do the following statements agree with the information given in the passage?

Write:

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

1. Automation has completely replaced human workers in manufacturing.

2. Automated systems can perform tasks with greater precision than humans.

3. Robots are used in the automotive industry for welding car bodies.

4. Automation has decreased the overall productivity of manufacturing processes.

5. The implementation of automation in manufacturing is always cost-effective.

Questions 6-10

Complete the sentences below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

6. Automation allows companies to meet consumer demands while maintaining high standards of ____.

7. Automated systems can collect and analyze ____ about the production process.

8. The ____ of implementing automation can be substantial for companies.

9. Employees often need ____ to operate and maintain automated systems.

10. As technology advances, we can expect to see more ____ automated systems in manufacturing.

Passage 2 – Medium Text

Quality Assurance Through Automation

The integration of automation into quality assurance processes has revolutionized the way companies ensure product excellence. This technological advancement has not only improved the accuracy of quality control but has also significantly reduced the time and resources required for inspection procedures.

One of the most notable applications of automation in quality assurance is the use of machine vision systems. These sophisticated optical inspection tools can detect defects and inconsistencies that might be imperceptible to the human eye. By employing high-resolution cameras and advanced image processing algorithms, machine vision systems can inspect thousands of products per minute with exceptional precision.

Another innovative technology enhancing product quality is the implementation of Internet of Things (IoT) devices throughout the manufacturing process. These interconnected sensors and devices continuously monitor various parameters such as temperature, humidity, and equipment performance. By collecting and analyzing this data in real-time, manufacturers can preemptively address issues that could potentially affect product quality.

The advent of artificial intelligence (AI) and machine learning has further amplified the capabilities of automated quality assurance systems. AI-powered algorithms can learn from historical data and adapt to new patterns, allowing for more nuanced and context-aware quality assessments. This predictive approach to quality control helps companies identify and rectify potential issues before they manifest in the final product.

Moreover, automation has enabled the development of digital twins – virtual replicas of physical products or processes. These digital models allow manufacturers to simulate and optimize production processes, predicting how changes in variables might affect product quality. This proactive approach to quality management has proven invaluable in industries where the margin for error is minimal, such as aerospace and pharmaceuticals.

While the benefits of automated quality assurance are evident, it’s crucial to acknowledge that human expertise remains indispensable. Skilled quality assurance professionals are still needed to interpret complex data, make nuanced decisions, and continuously improve automated systems. The most effective quality assurance strategies often involve a synergy between advanced automation and human insight.

As automation technology continues to evolve, we can anticipate even more sophisticated quality assurance methods. From nanotechnology-based sensors that can detect molecular-level defects to quantum computing applications that can process vast amounts of quality-related data, the future of automated quality assurance promises to push the boundaries of product excellence even further.

Questions 11-14

Choose the correct letter, A, B, C, or D.

11. According to the passage, machine vision systems:

A) Have replaced human inspectors entirely

B) Can detect defects invisible to the human eye

C) Are only used in specific industries

D) Are less accurate than manual inspection

12. The Internet of Things (IoT) devices in manufacturing:

A) Only monitor temperature and humidity

B) Replace traditional quality control methods

C) Continuously monitor various parameters

D) Are difficult to implement in existing factories

13. Artificial intelligence in quality assurance:

A) Completely eliminates the need for human involvement

B) Can only analyze historical data

C) Adapts to new patterns and allows for predictive quality control

D) Is only effective in large-scale manufacturing

14. Digital twins in manufacturing:

A) Are physical replicas of products

B) Allow for simulation and optimization of processes

C) Are only used in the aerospace industry

D) Replace traditional quality control methods

Questions 15-20

Complete the summary below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

Automation has revolutionized quality assurance in manufacturing. Technologies such as (15) ____ can detect minute defects, while (16) ____ monitor various parameters in real-time. (17) ____ enhances these systems by allowing them to learn and adapt. (18) ____ enable manufacturers to simulate and optimize processes. Despite these advancements, (19) ____ remain crucial for interpreting data and improving systems. Future developments may include (20) ____ for detecting molecular-level defects.

Passage 3 – Hard Text

The Paradigm Shift: Automation and the Future of Product Quality

The inexorable march of automation in manufacturing has ushered in a new era of product quality, fundamentally altering the landscape of industrial production. This transformative process, while rooted in the pursuit of efficiency and consistency, has far-reaching implications that extend beyond mere productivity gains. The symbiosis between automation and product quality represents a paradigm shift that is reshaping industries, consumer expectations, and the very definition of manufacturing excellence.

At the heart of this revolution lies the concept of precision engineering enabled by automation. Advanced robotics and computer numerical control (CNC) machines now operate with tolerances measured in microns, achieving a level of consistency that was once the domain of science fiction. This unprecedented accuracy has not only elevated the quality of end products but has also catalyzed innovation in fields such as nanotechnology and advanced materials science.

The integration of artificial intelligence (AI) and machine learning algorithms into automated quality control systems has engendered a proactive approach to defect prevention. These systems can analyze vast datasets, identifying subtle patterns and correlations that might elude even the most experienced human operators. By predicting potential quality issues before they materialize, manufacturers can implement corrective measures preemptively, drastically reducing defect rates and minimizing waste.

Moreover, the advent of edge computing and 5G technology has facilitated real-time monitoring and adjustment of manufacturing processes. This instantaneous feedback loop allows for dynamic optimization of production parameters, ensuring that each product meets or exceeds quality standards. The ability to make micro-adjustments on the fly represents a quantum leap in quality assurance, particularly in industries where environmental factors can significantly impact product integrity.

The proliferation of additive manufacturing, colloquially known as 3D printing, has introduced new paradigms in product customization and quality control. By enabling the production of complex geometries and internal structures that were previously impossible to manufacture, additive technologies have expanded the boundaries of product design. Concurrently, the layer-by-layer nature of 3D printing allows for unprecedented scrutiny of internal structures, facilitating a level of quality assurance that traditional manufacturing methods cannot match.

However, the automation of quality control is not without its challenges. The over-reliance on automated systems can lead to a false sense of security, potentially overlooking novel defects that fall outside predefined parameters. Furthermore, the complexity of these systems necessitates a highly skilled workforce capable of maintaining, calibrating, and interpreting the output of automated quality control mechanisms. This shift in skill requirements has profound implications for workforce development and education in the manufacturing sector.

The ethical dimensions of automated quality control also warrant consideration. As decision-making processes become increasingly algorithmic, questions arise regarding accountability and transparency. Who bears responsibility when an AI-driven quality control system fails to detect a critical flaw? How can we ensure that these systems do not inadvertently perpetuate biases or make decisions that prioritize efficiency over safety?

Looking ahead, the frontier of automated quality assurance lies in the realm of quantum sensing and cognitive manufacturing. Quantum sensors promise to detect defects at the atomic level, while cognitive systems may one day possess the ability to intuitively understand and optimize complex manufacturing processes in ways that surpass human comprehension. These advancements, while still in their infancy, hint at a future where the concept of “zero defects” transitions from aspirational goal to achievable reality.

In conclusion, the automation of quality control represents a seismic shift in manufacturing philosophy. By melding precision engineering with artificial intelligence and cutting-edge sensing technologies, automation is not merely improving product quality – it is redefining the very parameters of what constitutes a high-quality product. As this revolution continues to unfold, it will undoubtedly present both unprecedented opportunities and complex challenges for manufacturers, consumers, and society at large.

Questions 21-26

Complete the summary below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

Automation has brought about a paradigm shift in manufacturing, particularly in terms of (21) ____. Advanced robotics and CNC machines now operate with extremely fine (22) ____, enabling unprecedented accuracy. The integration of (23) ____ and machine learning allows for proactive defect prevention. (24) ____ and 5G technology facilitate real-time monitoring and adjustment of processes. (25) ____ has introduced new possibilities in product customization and quality control. However, the automation of quality control also presents challenges, including the risk of (26) ____ on automated systems.

Questions 27-30

Choose the correct letter, A, B, C, or D.

27. According to the passage, edge computing and 5G technology allow for:

A) Increased production speed

B) Better communication between machines

C) Real-time adjustments to ensure quality

D) Reduced energy consumption in manufacturing

28. The author suggests that additive manufacturing:

A) Is limited to simple product designs

B) Allows for better inspection of internal structures

C) Has replaced traditional manufacturing methods

D) Reduces the need for quality control

29. One of the challenges of automated quality control mentioned in the passage is:

A) The high cost of implementation

B) The need for a skilled workforce to manage complex systems

C) The inability to detect any defects

D) The slow speed of automated inspections

30. The passage indicates that future advancements in automated quality assurance may include:

A) Complete replacement of human workers

B) Quantum sensors detecting atomic-level defects

C) Elimination of all manufacturing defects

D) Reduction in product customization options

Answer Keys

Passage 1

1. FALSE

2. TRUE

3. TRUE

4. FALSE

5. NOT GIVEN

6. quality control

7. data

8. Initial costs

9. specialized training

10. sophisticated

Passage 2

11. B

12. C

13. C

14. B

15. machine vision systems

16. IoT devices

17. Artificial intelligence

18. Digital twins

19. Skilled quality assurance professionals

20. nanotechnology-based sensors

Passage 3

21. product quality

22. tolerances

23. artificial intelligence

24. Edge computing

25. Additive manufacturing

26. over-reliance

27. C

28. B

29. B

30. B

This IELTS Reading practice test on “How automation is improving product quality” covers various aspects of the topic, from basic concepts to advanced applications. It challenges your reading comprehension skills while providing valuable insights into the role of automation in enhancing product quality.

Remember to practice regularly and analyze your performance to improve your IELTS Reading skills. Good luck with your IELTS preparation!

For more IELTS practice materials, check out our articles on how automation is reshaping customer relationship management and the impact of automation on improving construction efficiency.