Welcome to our IELTS Reading practice session focused on the topic “How Automation is Improving Warehouse Management.” This comprehensive practice test will help you prepare for the IELTS Reading section by providing you with authentic passages and questions that mirror the real exam. Let’s dive into the world of warehouse automation and test your reading skills!

Passage 1 – Easy Text

The Rise of Automated Warehouses

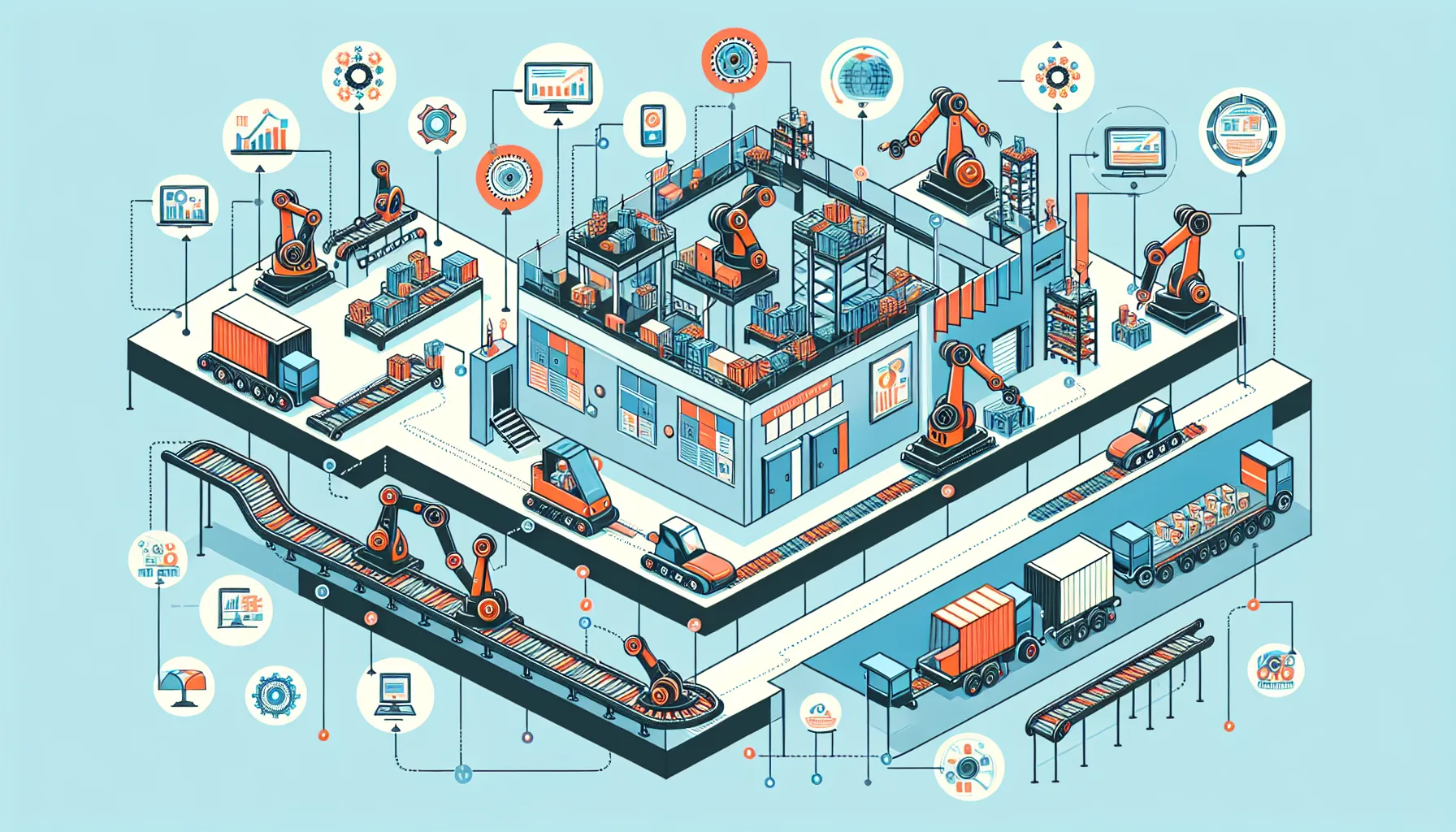

In recent years, the logistics industry has undergone a significant transformation, with automation playing a pivotal role in revolutionizing warehouse management. Traditional warehouses, once characterized by manual labor and paper-based systems, are rapidly evolving into high-tech facilities powered by cutting-edge technologies. This shift towards automation is driven by the need for increased efficiency, accuracy, and cost-effectiveness in the face of growing e-commerce demands and global supply chain complexities.

Automated warehouses employ a variety of technologies to streamline operations. Robotic systems, such as automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), navigate warehouse floors to transport goods with precision and speed. These robots work tirelessly, reducing the need for human intervention in repetitive tasks and minimizing the risk of errors and injuries.

Another key component of warehouse automation is the implementation of advanced inventory management systems. These systems utilize radio-frequency identification (RFID) tags and barcode scanners to track and monitor inventory in real-time. This technology enables warehouse managers to maintain accurate stock levels, reduce inventory discrepancies, and optimize storage space utilization.

The integration of artificial intelligence (AI) and machine learning algorithms further enhances warehouse operations. These technologies analyze vast amounts of data to predict demand patterns, optimize picking routes, and improve overall warehouse layout. By leveraging AI, warehouses can adapt to changing market conditions and customer preferences more effectively.

One of the most visible aspects of warehouse automation is the use of conveyor systems and sortation equipment. These mechanized systems efficiently move products through the warehouse, from receiving to storage and from picking to shipping. Advanced conveyor systems can handle a wide range of product sizes and weights, ensuring smooth and rapid product flow throughout the facility.

While the initial investment in automation technologies can be substantial, the long-term benefits are significant. Automated warehouses report increased productivity, reduced operating costs, and improved order accuracy. Moreover, automation helps address labor shortages and allows human workers to focus on higher-value tasks that require critical thinking and problem-solving skills.

As we move towards an increasingly digital future, the role of automation in warehouse management will continue to expand. The integration of Internet of Things (IoT) devices and cloud-based systems promises even greater levels of connectivity and data-driven decision-making. This ongoing evolution in warehouse automation is not just improving efficiency; it’s reshaping the entire landscape of supply chain management and logistics.

Questions 1-7

Do the following statements agree with the information given in the passage?

Write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

- Automated warehouses rely solely on robotic systems for all operations.

- RFID tags and barcode scanners help in maintaining accurate inventory levels.

- AI and machine learning are used to predict customer behavior and optimize warehouse layouts.

- Conveyor systems can only handle lightweight products in warehouses.

- The initial cost of implementing automation in warehouses is low.

- Automation in warehouses has led to the complete elimination of human workers.

- The Internet of Things (IoT) is expected to further enhance warehouse automation in the future.

Questions 8-13

Complete the sentences below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

- The shift towards automation in warehouses is driven by the need for increased efficiency, accuracy, and ____.

- ____ and autonomous mobile robots are examples of robotic systems used in automated warehouses.

- Advanced inventory management systems help optimize ____ utilization in warehouses.

- Conveyor systems and sortation equipment are responsible for the ____ of products through the warehouse.

- Automated warehouses allow human workers to focus on tasks that require ____ and problem-solving skills.

- The integration of ____ devices promises greater connectivity in future warehouse automation.

Passage 2 – Medium Text

The Impact of Automation on Warehouse Workforce and Productivity

The proliferation of automation in warehouse management has sparked a significant debate about its impact on the workforce and overall productivity. While some view automation as a threat to jobs, others see it as an opportunity for workforce evolution and enhanced operational efficiency. This complex interplay between technology and human labor is reshaping the landscape of warehouse employment and redefining productivity metrics in the logistics sector.

One of the most immediate effects of automation has been the reduction in manual labor requirements for routine tasks. Automated guided vehicles (AGVs), robotic arms, and conveyor systems have taken over many of the physically demanding and repetitive jobs traditionally performed by warehouse workers. This shift has led to concerns about job displacement, particularly for low-skilled workers. However, proponents of automation argue that it also creates new job opportunities in areas such as robotics maintenance, data analysis, and systems management.

The introduction of automated systems has undeniably boosted warehouse productivity. Advanced picking systems, for instance, can operate 24/7 without fatigue, significantly increasing the volume of orders processed. These systems also boast higher accuracy rates, reducing errors in order fulfillment and minimizing returns. The efficiency gains are substantial, with some automated warehouses reporting productivity increases of up to 300% compared to traditional setups.

However, the true impact of automation on warehouse productivity goes beyond mere speed and accuracy. Automated warehouses benefit from improved space utilization, as robots can navigate narrower aisles and reach higher shelves than human workers. This optimization of warehouse layout allows for higher storage density and more efficient use of available space. Furthermore, automated inventory management systems provide real-time visibility into stock levels, enabling more precise inventory control and reducing the costs associated with overstocking or stockouts.

The human element remains crucial in automated warehouses, albeit in evolving roles. While some jobs have been replaced by machines, new positions have emerged that require a different skill set. Warehouse workers are increasingly taking on roles that involve overseeing automated systems, troubleshooting technical issues, and making strategic decisions based on data insights. This shift demands a workforce with higher technological literacy and problem-solving abilities.

The integration of automation has also led to improvements in workplace safety. By reducing the need for human workers to perform dangerous tasks such as operating heavy machinery or working at heights, automation has contributed to a decrease in workplace accidents and injuries. This not only benefits workers but also reduces costs associated with workplace compensation and lost productivity due to accidents.

Despite these advantages, the transition to automated warehouses is not without challenges. The initial investment in automation technology can be substantial, and there is often a learning curve associated with implementing and optimizing these systems. Additionally, there are concerns about the digital divide that may be created between workers who can adapt to new technologies and those who cannot.

Looking ahead, the future of warehouse automation seems poised for further innovation. Emerging technologies such as augmented reality (AR) for picking guidance, exoskeletons to assist human workers, and advanced AI for predictive maintenance are on the horizon. These developments promise to further enhance productivity while creating new synergies between human workers and automated systems.

In conclusion, while automation in warehouse management has certainly disrupted traditional employment patterns, it has also driven significant improvements in productivity and efficiency. The key to harnessing the full potential of warehouse automation lies in striking a balance between technological advancement and workforce development. As the industry continues to evolve, adaptability and continuous learning will be crucial for both workers and organizations in the automated warehouse landscape.

Questions 14-19

Choose the correct letter, A, B, C, or D.

-

The main debate surrounding warehouse automation centers on:

A) Its cost-effectiveness

B) Its impact on job market and productivity

C) The speed of technological advancements

D) The reliability of automated systems -

According to the passage, automated warehouses have reported productivity increases of up to:

A) 100%

B) 200%

C) 300%

D) 400% -

The text suggests that in automated warehouses, human workers are increasingly taking on roles that involve:

A) Manual labor

B) Customer service

C) Overseeing automated systems

D) Marketing and sales -

One of the benefits of automation in warehouses mentioned in the passage is:

A) Increased workplace accidents

B) Reduced need for skilled workers

C) Improved workplace safety

D) Higher employee satisfaction -

The passage indicates that one of the challenges in transitioning to automated warehouses is:

A) The high initial investment

B) Lack of government support

C) Resistance from customers

D) Decreased productivity -

According to the text, which of the following is an emerging technology in warehouse automation?

A) Conveyor belts

B) Barcode scanners

C) Augmented reality for picking guidance

D) RFID tags

Questions 20-26

Complete the summary below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

The impact of automation on warehouse management has been significant, leading to both challenges and opportunities. While automation has reduced the need for 20)____ in routine tasks, it has also created new job roles in areas such as robotics maintenance and data analysis. Automated warehouses have seen substantial gains in 21)____, with some reporting increases of up to 300%. These improvements are due to factors such as 24/7 operation, higher accuracy, and better 22)____.

The role of human workers in automated warehouses has evolved, with an increasing focus on 23)____ and making strategic decisions based on data. This shift requires workers with higher 24)____ and problem-solving abilities. Automation has also contributed to improvements in 25)____, reducing workplace accidents and associated costs.

Despite these benefits, the transition to automated warehouses faces challenges, including high 26)____ and the potential creation of a digital divide among workers. The future of warehouse automation looks promising, with emerging technologies set to further enhance productivity and create new synergies between humans and machines.

Passage 3 – Hard Text

The Synergy of Automation and Sustainability in Modern Warehouse Management

The convergence of automation technologies and sustainability initiatives in warehouse management is ushering in a new era of operational efficiency and environmental responsibility. This symbiotic relationship between cutting-edge automation and eco-friendly practices is not only revolutionizing the logistics industry but also setting new standards for corporate social responsibility in the supply chain sector.

At the forefront of this paradigm shift is the implementation of energy-efficient automated systems. Modern warehouses are increasingly adopting solar-powered robotics and energy-recuperation technologies in their automated guided vehicles (AGVs) and conveyor systems. These innovations significantly reduce the carbon footprint of warehouse operations while simultaneously enhancing productivity. For instance, regenerative braking systems in AGVs can recapture up to 30% of the energy used during deceleration, which is then redirected to power other warehouse functions.

The integration of artificial intelligence (AI) and machine learning algorithms in warehouse management systems has led to unprecedented levels of optimization in resource utilization. These sophisticated systems analyze vast amounts of data to predict energy consumption patterns, optimize lighting and HVAC systems, and minimize waste in real-time. By leveraging AI, warehouses can achieve a delicate balance between operational demands and energy conservation, resulting in substantial reductions in both costs and environmental impact.

Another critical aspect of the automation-sustainability nexus is the optimization of warehouse space. Automated storage and retrieval systems (AS/RS) enable warehouses to maximize vertical space utilization, significantly reducing the physical footprint of facilities. This vertical expansion not only conserves land but also minimizes the energy required for climate control and lighting. Moreover, the precision of automated systems in inventory management leads to a reduction in overstock situations, thereby decreasing the waste associated with expired or obsolete products.

The advent of smart packaging solutions in automated warehouses is addressing the perennial issue of packaging waste in the supply chain. Automated systems equipped with 3D scanning technology can now determine the optimal package size for each item, reducing excess packaging material and void fill. This not only decreases the environmental impact of shipping but also optimizes transportation efficiency by reducing the volume of shipments.

Predictive maintenance, powered by IoT sensors and AI analytics, is another area where automation is driving sustainability in warehouses. By anticipating equipment failures and scheduling preemptive maintenance, these systems minimize downtime and extend the lifespan of warehouse machinery. This proactive approach not only enhances operational efficiency but also reduces the environmental impact associated with the premature disposal and replacement of equipment.

The integration of blockchain technology with automated warehouse systems is paving the way for enhanced transparency and traceability in supply chains. This synergy enables real-time tracking of products from source to destination, ensuring compliance with sustainability standards and facilitating the verification of eco-friendly practices throughout the supply chain. Such transparency is increasingly crucial in meeting consumer demands for ethically sourced and sustainably produced goods.

However, the marriage of automation and sustainability in warehouse management is not without its challenges. The initial capital investment required for implementing these advanced systems can be substantial, potentially creating a barrier for smaller organizations. Additionally, the rapid pace of technological advancement in this field necessitates continuous upgrades and training, which can strain resources and potentially lead to technological obsolescence.

There are also concerns about the e-waste generated by the frequent upgrading of automated systems. As warehouses strive to stay at the cutting edge of technology, the disposal of outdated equipment poses a significant environmental challenge. This has led to calls for more robust recycling programs and the development of modular, upgradeable automation systems that can extend the lifecycle of warehouse technology.

Despite these challenges, the potential benefits of integrating automation and sustainability in warehouse management are too significant to ignore. As the technology continues to evolve, we can expect to see even more innovative solutions that further reduce environmental impact while enhancing operational efficiency. The warehouses of the future will likely be characterized by zero-emission robotics, self-sufficient energy systems, and closed-loop material flows that minimize waste and maximize resource utilization.

In conclusion, the synergy between automation and sustainability in warehouse management represents a transformative force in the logistics industry. By harnessing the power of technology to drive both efficiency and environmental responsibility, warehouses are not only optimizing their operations but also contributing to broader sustainability goals. As this trend continues to gain momentum, it will undoubtedly play a crucial role in shaping the future of global supply chains and setting new benchmarks for sustainable business practices.

Questions 27-32

Complete the sentences below.

Choose NO MORE THAN THREE WORDS from the passage for each answer.

- Energy-recuperation technologies in AGVs can recapture up to ____ of the energy used during deceleration.

- AI and machine learning algorithms help warehouses balance ____ and energy conservation.

- Automated storage and retrieval systems enable warehouses to maximize ____, reducing their physical footprint.

- Smart packaging solutions in automated warehouses use ____ to determine the optimal package size for each item.

- ____, powered by IoT sensors and AI analytics, helps extend the lifespan of warehouse machinery.

- The integration of ____ with automated warehouse systems enhances transparency and traceability in supply chains.

Questions 33-37

Do the following statements agree with the information given in the passage?

Write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

- Solar-powered robotics are becoming increasingly common in modern automated warehouses.

- The optimization of warehouse space through automation always leads to a reduction in energy costs.

- Blockchain technology in warehouse automation helps verify compliance with sustainability standards.

- The implementation of automated systems in warehouses is equally accessible to all sizes of organizations.

- Future warehouses are expected to operate with completely self-sufficient energy systems.

Questions 38-40

Choose the correct letter, A, B, C, or D.

-

According to the passage, one of the challenges in implementing automated and sustainable warehouse systems is:

A) Lack of consumer interest in sustainable products

B) Difficulty in integrating different technologies

C) The high initial capital investment required

D) Resistance from warehouse employees -

The issue of e-waste in automated warehouses is primarily caused by:

A) Improper disposal of packaging materials

B) Frequent upgrading of automated systems

C) Overproduction of goods

D) Inefficient energy use -

The passage suggests that the future of warehouse automation and sustainability will likely include:

A) Complete elimination of human workers

B) Reduced focus on environmental impact

C) Zero-emission robotics and closed-loop material flows

D) Decreased reliance on artificial intelligence

Answer Key

Passage 1 – Easy Text

- FALSE

- TRUE

- TRUE

- FALSE

- FALSE

- FALSE

- TRUE

- cost-effectiveness

- Automated guided vehicles

- storage space

- efficient movement

- critical thinking

- IoT

Passage 2 – Medium Text

- B

- C

- C

- C

- A

- C

- manual labor

- productivity

- space utilization

- overseeing automated systems

- technological literacy

- workplace safety

- initial investment