Are you preparing for the IELTS Reading test and looking to practice with a relevant and engaging topic? Look no further! In this article, we’ll explore how automation is revolutionizing industrial production by reducing waste, while providing you with a comprehensive IELTS Reading practice test. As an experienced IELTS instructor, I’ve crafted this practice material to closely resemble the actual IELTS exam, complete with passages of varying difficulty and a range of question types. Let’s dive in and enhance your reading skills while learning about this fascinating subject!

Nội dung bài viết

IELTS Reading Practice Test

Passage 1 – Easy Text

Automation: A Game-Changer in Waste Reduction

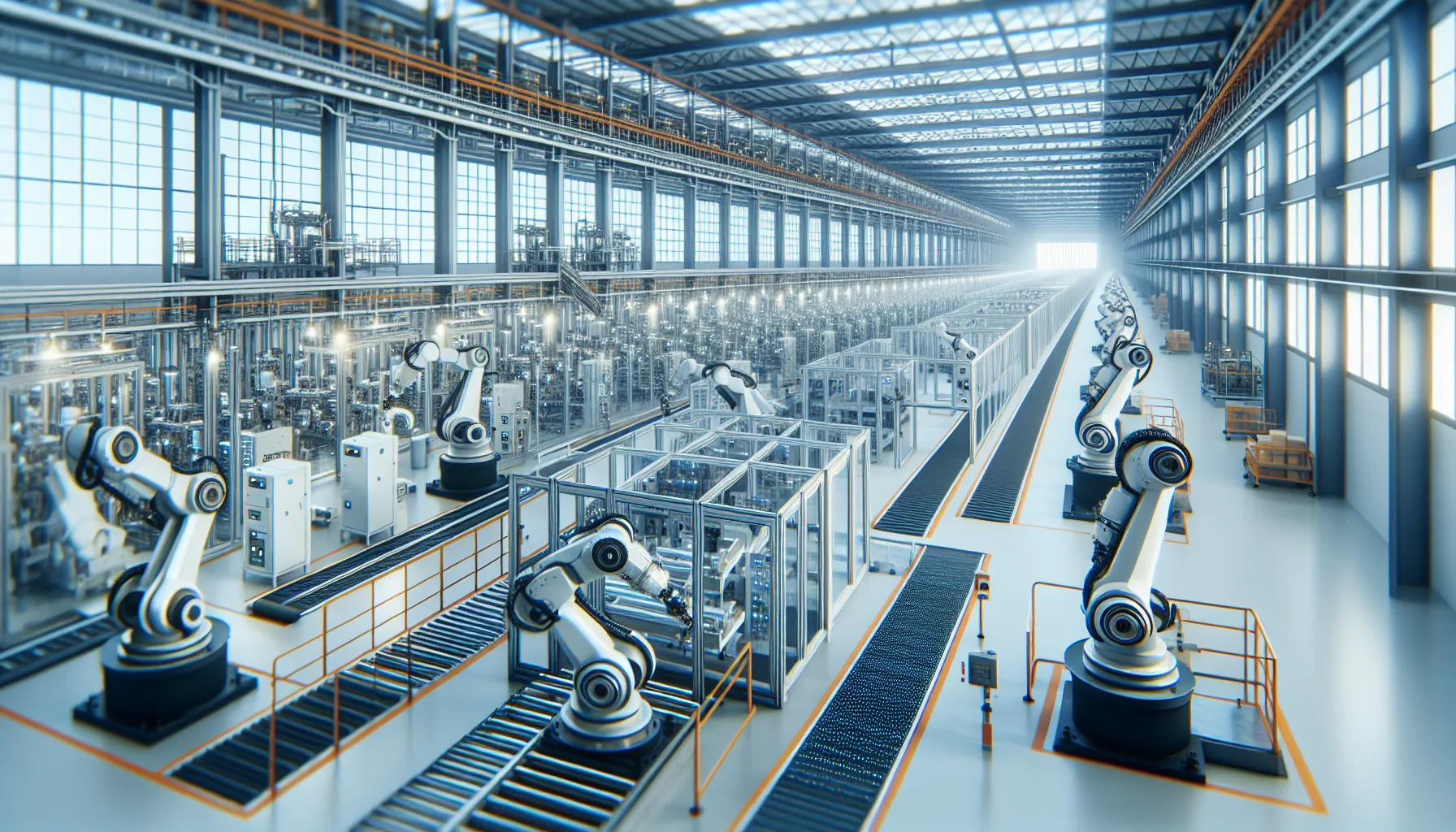

Automation has emerged as a pivotal force in transforming industrial production processes, particularly in the realm of waste reduction. As manufacturers face increasing pressure to minimize their environmental impact and optimize resource utilization, automated systems have become indispensable tools in achieving these goals.

One of the primary ways automation contributes to waste reduction is through precise control of production processes. Automated systems can monitor and adjust various parameters in real-time, ensuring that raw materials are used efficiently and products meet exact specifications. This level of precision significantly reduces the occurrence of defective items and overproduction, two major sources of waste in traditional manufacturing settings.

Moreover, automated inventory management systems play a crucial role in minimizing waste associated with stockpiling and obsolescence. These systems can accurately track inventory levels, predict demand, and optimize order quantities, reducing the likelihood of excess stock that may become obsolete or expire before use.

In the packaging industry, automation has led to remarkable improvements in material efficiency. Automated packaging lines can precisely measure and cut materials, reducing excess packaging and minimizing offcuts. Additionally, advanced vision systems can detect and reject defective packaging, ensuring that only high-quality materials are used.

The integration of artificial intelligence (AI) and machine learning algorithms into automated systems has further enhanced waste reduction efforts. These technologies can analyze vast amounts of data to identify patterns and inefficiencies in production processes, allowing for continuous optimization and waste minimization.

As industries continue to embrace automation, the potential for waste reduction grows exponentially. From smart factories that optimize energy consumption to automated recycling systems that efficiently sort and process waste materials, the applications of automation in waste reduction are diverse and far-reaching.

In conclusion, automation has proven to be a powerful ally in the fight against industrial waste. By improving precision, optimizing resource utilization, and enabling data-driven decision-making, automated systems are helping industries move towards more sustainable and efficient production models.

Questions 1-7

Do the following statements agree with the information given in the passage? Write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

- Automation has become an essential tool for manufacturers aiming to reduce their environmental impact.

- Automated systems can only monitor production processes but cannot make real-time adjustments.

- Precise control in automated systems helps reduce the production of defective items.

- Automated inventory management systems can accurately predict future demand.

- The packaging industry has seen no improvements in material efficiency due to automation.

- Artificial intelligence and machine learning are used to analyze production data for optimization.

- All industries have fully embraced automation for waste reduction.

Questions 8-13

Complete the sentences below. Choose NO MORE THAN THREE WORDS from the passage for each answer.

- Automation contributes to waste reduction through __ of production processes.

- Two major sources of waste in traditional manufacturing are defective items and __.

- Automated inventory management systems help minimize waste associated with stockpiling and __.

- In the packaging industry, __ can detect and reject defective packaging.

- The integration of AI and machine learning allows for __ and waste minimization.

- Smart factories optimize __ as part of their waste reduction efforts.

Passage 2 – Medium Text

The Role of Automation in Circular Economy Practices

The concept of a circular economy, which aims to eliminate waste and maximize resource efficiency, has gained significant traction in recent years. Automation technologies play a pivotal role in enabling and enhancing circular economy practices within industrial production. By leveraging advanced sensors, data analytics, and robotic systems, manufacturers can implement more effective recycling, remanufacturing, and resource recovery processes.

One of the key areas where automation contributes to circular economy principles is in material sorting and recycling. Traditional manual sorting methods are often inefficient and prone to errors, leading to contamination and reduced recycling rates. Automated sorting systems, equipped with optical sensors and artificial intelligence, can rapidly and accurately identify different materials, even when they are mixed or contaminated. This technology has revolutionized recycling facilities, significantly increasing the volume and quality of recovered materials.

In the realm of remanufacturing, automation has enabled more efficient disassembly and refurbishment processes. Robotic systems can quickly and precisely disassemble products, separating components for reuse, repair, or recycling. This level of precision and speed would be impossible to achieve through manual labor alone. Furthermore, automated testing and quality control systems ensure that remanufactured products meet the same standards as new ones, boosting consumer confidence in refurbished goods.

Automation also plays a crucial role in optimizing resource recovery from industrial waste streams. Advanced sensors and control systems can continuously monitor waste outputs, identifying valuable materials that can be extracted and reprocessed. For instance, in the metallurgical industry, automated systems can analyze slag compositions in real-time, enabling the recovery of residual metals that would otherwise be lost.

The integration of Internet of Things (IoT) devices and big data analytics has further enhanced the potential for automation in circular economy practices. By collecting and analyzing data throughout the product lifecycle, manufacturers can identify opportunities for waste reduction and resource optimization. This data-driven approach enables predictive maintenance, reducing equipment failures and associated waste, and helps in designing products that are more easily recyclable or repairable.

Moreover, automation facilitates the implementation of product-as-a-service models, which align with circular economy principles. Through remote monitoring and automated servicing, companies can maintain and repair products more efficiently, extending their lifespan and reducing waste.

However, the transition to automated circular economy practices is not without challenges. Initial investment costs can be high, and there is a need for specialized skills to operate and maintain these advanced systems. Additionally, as automation reduces the need for manual labor in certain areas, there is a growing imperative to reskill workers for new roles within the circular economy framework.

Despite these challenges, the potential of automation to drive circular economy practices in industrial production is immense. As technologies continue to evolve and become more accessible, we can expect to see even greater advancements in waste reduction and resource efficiency across various industries.

Questions 14-19

Choose the correct letter, A, B, C, or D.

-

According to the passage, the circular economy concept aims to:

A) Increase industrial production

B) Eliminate waste and maximize resource efficiency

C) Promote manual sorting methods

D) Reduce the use of automation in industries -

Automated sorting systems in recycling facilities:

A) Are less efficient than manual sorting

B) Can only identify pure materials

C) Have decreased recycling rates

D) Can accurately identify mixed or contaminated materials -

In remanufacturing processes, automation enables:

A) Slower disassembly of products

B) Less precise separation of components

C) More efficient disassembly and refurbishment

D) Lower quality standards for refurbished products -

The integration of IoT devices and big data analytics in circular economy practices:

A) Has no impact on waste reduction

B) Hinders product lifecycle analysis

C) Enables predictive maintenance and better product design

D) Increases equipment failures -

The product-as-a-service model, facilitated by automation:

A) Shortens product lifespan

B) Increases waste generation

C) Makes product maintenance more difficult

D) Extends product lifespan and reduces waste -

One of the challenges in transitioning to automated circular economy practices is:

A) Decreased efficiency in recycling processes

B) Lower quality of remanufactured products

C) High initial investment costs

D) Reduced potential for waste reduction

Questions 20-26

Complete the summary below. Choose NO MORE THAN TWO WORDS from the passage for each answer.

Automation plays a crucial role in implementing circular economy practices in industrial production. In material sorting and recycling, automated systems equipped with (20) __ and artificial intelligence can accurately identify different materials. For remanufacturing, (21) __ can efficiently disassemble products, while automated testing ensures high quality of refurbished goods. In resource recovery, advanced sensors monitor waste outputs to identify (22) __ that can be extracted. The integration of (23) __ devices and big data analytics enhances waste reduction potential throughout the product lifecycle. Automation also facilitates (24) __ models, which align with circular economy principles. However, challenges include high (25) __ and the need to (26) __ for new roles in the circular economy framework.

Passage 3 – Hard Text

The Synergy of Automation and Lean Manufacturing in Waste Reduction

The integration of automation technologies with lean manufacturing principles has ushered in a new era of waste reduction in industrial production. This synergistic approach, often referred to as “Lean Automation,” combines the efficiency and precision of automated systems with the waste-elimination focus of lean methodologies, resulting in unprecedented levels of operational excellence and resource optimization.

Lean manufacturing, pioneered by Toyota in the mid-20th century, is fundamentally concerned with identifying and eliminating various forms of waste, or “muda” in Japanese. These wastes traditionally include overproduction, waiting, unnecessary transport, over-processing, excess inventory, unnecessary movement, and defects. Automation, when thoughtfully implemented within this framework, serves as a powerful tool to address these waste categories systematically.

One of the most significant contributions of automation to lean practices is in the realm of continuous flow production. Automated guided vehicles (AGVs) and conveyor systems, when integrated with just-in-time (JIT) principles, can create seamless material flow, drastically reducing waiting times and work-in-process inventory. These systems can be programmed to deliver components precisely when and where they are needed, eliminating the waste of unnecessary movement and transport.

Moreover, advanced vision systems and sensor technologies play a crucial role in defect reduction, a key tenet of lean manufacturing. These automated quality control mechanisms can detect deviations from specifications with a level of accuracy and consistency that surpasses human capabilities. By identifying defects early in the production process, these systems prevent the waste of further processing defective items and reduce the likelihood of defective products reaching customers.

The implementation of Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software automates data collection and analysis, providing real-time visibility into production processes. This aligns closely with the lean principle of visual management, enabling quick identification of bottlenecks, inefficiencies, and opportunities for improvement. The data-driven insights generated by these systems facilitate more effective problem-solving and continuous improvement initiatives, or “kaizen” in lean terminology.

Automation also addresses the lean concept of “jidoka”, or autonomation, which refers to intelligent automation with human touch. Collaborative robots, or cobots, exemplify this principle by working alongside human operators, automating repetitive or ergonomically challenging tasks while allowing humans to focus on more value-added activities. This human-machine collaboration optimizes the overall production process, reducing the waste of human potential and improving workplace ergonomics.

In the context of changeovers and setup reduction, a critical aspect of lean manufacturing, automation has enabled significant advancements. Programmable logic controllers (PLCs) and servo motors allow for rapid and precise adjustments to equipment settings, drastically reducing setup times between product runs. This capability aligns with the lean tool of Single-Minute Exchange of Die (SMED), facilitating smaller batch sizes and greater production flexibility without sacrificing efficiency.

The Internet of Things (IoT) and edge computing technologies have further enhanced the synergy between automation and lean principles. By enabling real-time monitoring and control of equipment performance, these technologies support predictive maintenance strategies, reducing unplanned downtime and the associated wastes of waiting and underutilized capacity.

However, it is crucial to note that the successful integration of automation within a lean framework requires a nuanced approach. The over-application of automation can sometimes lead to increased complexity and rigidity, potentially contradicting lean principles of simplicity and flexibility. Therefore, organizations must carefully assess where automation adds value and where traditional lean tools remain more appropriate.

Furthermore, the human element remains indispensable in this lean automation paradigm. While automation excels at executing repetitive tasks and processing vast amounts of data, human creativity, problem-solving skills, and adaptability are essential for continuous improvement and innovation. The challenge lies in fostering a culture where workers are empowered to leverage automation as a tool for waste reduction rather than viewing it as a threat to their roles.

In conclusion, the convergence of automation and lean manufacturing principles represents a powerful approach to waste reduction in industrial production. By thoughtfully integrating automated technologies within a lean framework, organizations can achieve new levels of efficiency, quality, and resource optimization. As these technologies continue to evolve, the potential for further waste reduction and operational excellence in manufacturing remains boundless, promising a future of increasingly sustainable and efficient industrial practices.

Questions 27-32

Complete the sentences below. Choose NO MORE THAN TWO WORDS from the passage for each answer.

- The combination of automation technologies and lean manufacturing principles is often referred to as __.

- In lean manufacturing, the various forms of waste are collectively known as __ in Japanese.

- Automated guided vehicles and conveyor systems, when integrated with JIT principles, can create __ production.

- The lean manufacturing principle of intelligent automation with human touch is called __.

- Programmable logic controllers and servo motors allow for rapid adjustments, aligning with the lean tool called __.

- The over-application of automation can sometimes contradict lean principles of __ and flexibility.

Questions 33-37

Do the following statements agree with the claims of the writer in the passage? Write

YES if the statement agrees with the claims of the writer

NO if the statement contradicts the claims of the writer

NOT GIVEN if it is impossible to say what the writer thinks about this

- Automation always improves the efficiency of lean manufacturing processes.

- Vision systems and sensor technologies can detect defects more accurately than humans.

- Manufacturing Execution Systems and Enterprise Resource Planning software hinder visual management in lean manufacturing.

- Collaborative robots completely replace human workers in manufacturing processes.

- The integration of automation within a lean framework requires careful assessment of where it adds value.

Questions 38-40

Choose the correct letter, A, B, C, or D.

-

According to the passage, which of the following is NOT mentioned as a traditional form of waste in lean manufacturing?

A) Overproduction

B) Unnecessary transport

C) Excess inventory

D) Excessive automation -

The Internet of Things and edge computing technologies support waste reduction by:

A) Increasing production speed

B) Enabling predictive maintenance

C) Replacing human workers

D) Simplifying product designs -

The passage suggests that in the lean automation paradigm:

A) Human workers are no longer necessary

B) Automation should be applied uniformly across all processes

C) Human creativity and problem-solving skills remain essential

D) Traditional lean tools are obsolete

Answer Key

Passage 1

- TRUE

- FALSE

- TRUE

- TRUE

- FALSE

- TRUE

- NOT GIVEN

- precise control

- overproduction

- obsolescence

- advanced vision systems

- continuous optimization

- energy consumption

Passage 2

- B

- D

- C

- C

- D

- C

- optical sensors

- Robotic systems

- valuable materials

- Internet of Things (IoT)

- product-as-a-service

- initial investment costs

- reskill workers

Passage 3

- Lean Automation

- muda

- continuous flow

- jidoka

- Single-Minute Exchange of Die

- simplicity

- NO

- YES

- NO

- NO

- YES

- D

- B

- C

By practicing with this IELTS Reading test on how automation is reducing waste in industrial production, you’ve not only enhanced your reading skills but also gained valuable insights into this important topic. Remember to apply the strategies we’ve discussed, such as identifying key information, understanding context, and managing your time effectively. Keep practicing regularly, and you’ll be well-prepared for success in your IELTS Reading test!

For more IELTS preparation resources and practice materials, be sure to check out our other articles on how automation is transforming global agriculture and the impact of automation on the automotive industry. Good luck with your IELTS journey!