The IELTS Reading test often includes passages on technological advancements and their impact on various industries. One such topic that frequently appears is the “Impact of automation on reducing human error in manufacturing.” This article provides a comprehensive practice test focusing on this subject, complete with three passages of increasing difficulty and a variety of question types to help you prepare for the IELTS Reading exam.

IELTS Reading Practice Test

Passage 1 – Easy Text

The Rise of Automation in Manufacturing

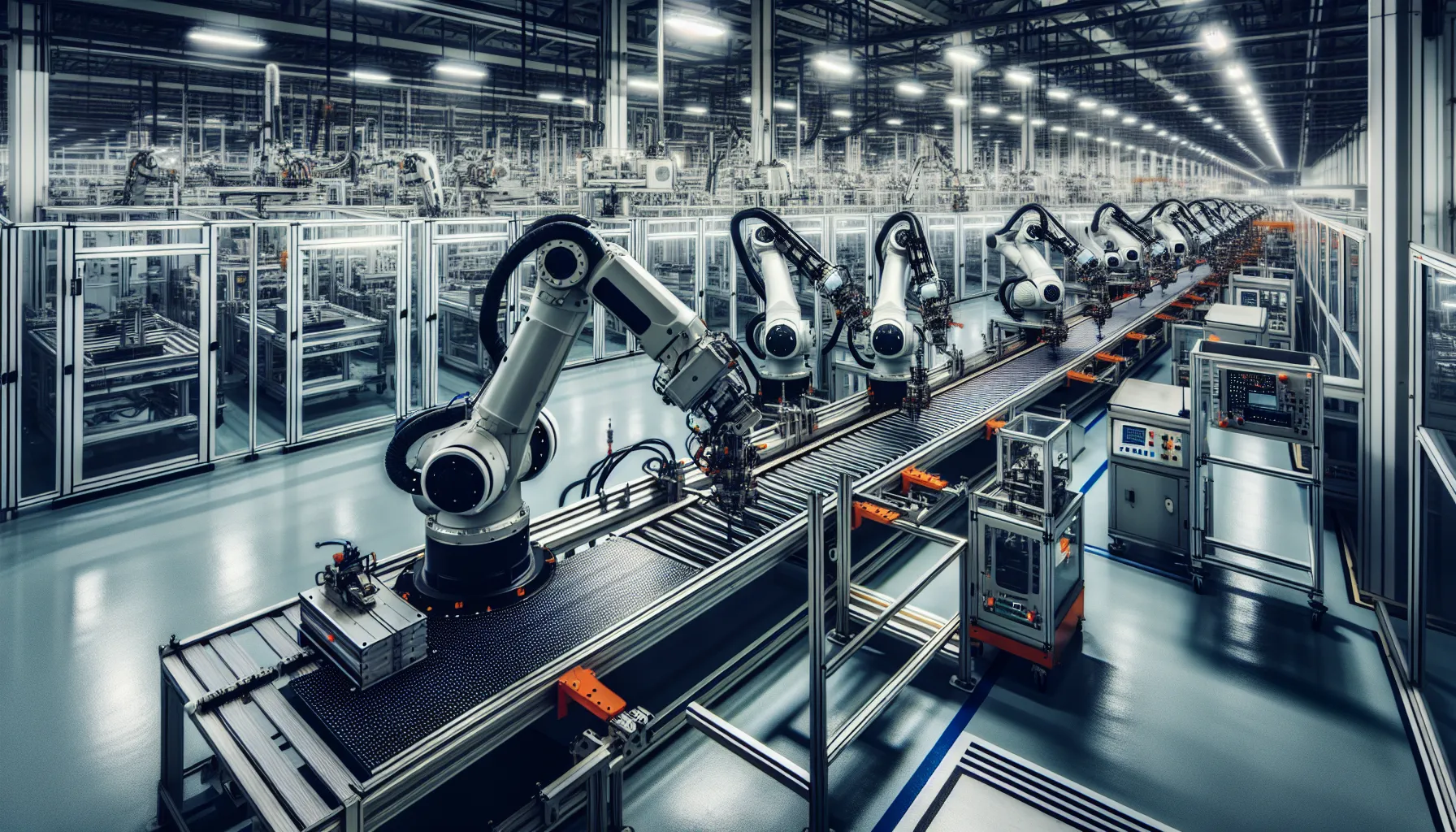

Automation has become an increasingly important aspect of modern manufacturing processes. As industries strive for greater efficiency and precision, the implementation of automated systems has proven to be a game-changer in reducing human error and improving overall productivity.

One of the primary benefits of automation in manufacturing is its ability to perform repetitive tasks with unparalleled consistency. Unlike human workers who may experience fatigue or lapses in concentration, automated systems can operate continuously without variation in performance. This consistency is particularly crucial in industries where precision is paramount, such as electronics or pharmaceutical manufacturing.

Moreover, automated systems are equipped with advanced sensors and monitoring capabilities that can detect errors or anomalies in real-time. This early detection allows for immediate corrective action, preventing defective products from progressing further down the production line. In contrast, human quality control inspectors may miss subtle defects, especially during long shifts or when dealing with high-volume production.

Another significant advantage of automation is its ability to handle complex calculations and data processing tasks. In manufacturing environments that require precise measurements or intricate assembly processes, automated systems can perform these operations with a level of accuracy that surpasses human capabilities. This is particularly evident in industries such as automotive manufacturing, where robots are used for tasks like welding and painting, ensuring consistent quality across thousands of units.

While the implementation of automation does require a significant initial investment, the long-term benefits in terms of reduced errors, increased productivity, and improved safety often outweigh the costs. As technology continues to advance, the role of automation in manufacturing is likely to expand further, revolutionizing the industry and setting new standards for precision and efficiency.

Questions 1-5

Do the following statements agree with the information given in the reading passage?

Write

TRUE if the statement agrees with the information

FALSE if the statement contradicts the information

NOT GIVEN if there is no information on this

- Automated systems can work continuously without variations in performance.

- Human workers are more efficient than automated systems in detecting subtle defects.

- Automation is particularly useful in industries requiring precise measurements.

- The initial cost of implementing automation is always lower than the long-term benefits.

- Automation in manufacturing is expected to become more prevalent in the future.

Questions 6-10

Complete the sentences below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

- Automation helps perform __ tasks with great consistency.

- Advanced sensors in automated systems can detect errors in __.

- Automated systems are better at handling __ and data processing tasks compared to humans.

- In automotive manufacturing, robots are used for tasks like welding and __.

- The implementation of automation requires a significant __ investment.

Passage 2 – Medium Text

Human Error Reduction through Automation: A Closer Look

The integration of automated systems in manufacturing environments has led to a significant reduction in human error, a persistent challenge that has plagued industries for decades. This shift towards automation is not merely about replacing human workers but rather about optimizing the production process by leveraging the strengths of both humans and machines.

One of the primary ways automation reduces human error is by eliminating the variability inherent in manual tasks. For instance, in pharmaceutical manufacturing, automated systems can measure and mix ingredients with pinpoint accuracy, ensuring consistent product quality. This level of precision is difficult, if not impossible, for human operators to maintain over extended periods, especially when dealing with microscopic quantities.

Moreover, automation systems are equipped with sophisticated error-detection mechanisms. These systems can identify deviations from predetermined parameters almost instantaneously, allowing for rapid intervention before a small error escalates into a major problem. This proactive approach to error management is particularly crucial in high-stakes industries such as aerospace manufacturing, where even minor mistakes can have catastrophic consequences.

Another significant advantage of automation in error reduction is its immunity to human factors such as fatigue, distraction, or emotional stress. In industries that operate around the clock, human performance inevitably deteriorates during night shifts or extended work hours. Automated systems, on the other hand, maintain consistent performance regardless of the time of day or duration of operation.

Furthermore, automation facilitates better data collection and analysis. By continuously monitoring production processes, automated systems generate vast amounts of data that can be analyzed to identify patterns, trends, and potential areas for improvement. This data-driven approach allows manufacturers to implement preventive measures and optimize their processes continuously, further reducing the likelihood of errors.

However, it’s important to note that the implementation of automation is not without challenges. The transition requires significant investment in technology and training. Additionally, there’s a need for skilled personnel to operate, maintain, and troubleshoot these advanced systems. Despite these challenges, the long-term benefits of reduced errors, improved quality, and increased productivity make automation an attractive proposition for many manufacturers.

As we look to the future, the role of automation in reducing human error is likely to expand further. Emerging technologies such as artificial intelligence and machine learning promise to enhance the capabilities of automated systems, enabling them to adapt and learn from past errors, potentially leading to even greater reductions in manufacturing errors.

Questions 11-14

Choose the correct letter, A, B, C, or D.

-

According to the passage, the main purpose of integrating automation in manufacturing is to:

A) Replace human workers entirely

B) Optimize production by combining human and machine strengths

C) Reduce the cost of production

D) Increase production speed -

In pharmaceutical manufacturing, automated systems are particularly useful for:

A) Quality control

B) Packaging

C) Measuring and mixing ingredients

D) Marketing products -

The passage suggests that automation is especially important in aerospace manufacturing because:

A) It increases production speed

B) It reduces labor costs

C) Minor errors can have severe consequences

D) It improves worker safety -

According to the text, one challenge in implementing automation is:

A) The need for significant investment in technology and training

B) Resistance from workers

C) Lack of government support

D) Difficulty in sourcing automated equipment

Questions 15-20

Complete the summary below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

Automation in manufacturing significantly reduces human error by eliminating the 15) __ inherent in manual tasks. Sophisticated 16) __ mechanisms in automated systems can quickly identify deviations from set parameters. Unlike humans, automated systems are not affected by factors such as 17) __ or emotional stress, maintaining consistent performance. These systems also facilitate better 18) __ and analysis, allowing for continuous process optimization. Despite challenges in implementation, the long-term benefits include reduced errors, improved quality, and increased 19) __. Future developments in 20) __ and machine learning are expected to further enhance the capabilities of automated systems in reducing manufacturing errors.

Passage 3 – Hard Text

The Symbiosis of Human Expertise and Automation in Error Reduction

The discourse surrounding automation in manufacturing often polarizes into two camps: those who herald it as a panacea for human error and those who view it as a threat to human employment. However, a more nuanced examination reveals that the most effective approach to error reduction lies in the synergistic integration of human expertise and automated systems. This symbiotic relationship leverages the unique strengths of both elements to create a manufacturing environment that is not only more efficient but also more resilient to errors.

While automated systems excel at performing repetitive tasks with unwavering precision and can process vast amounts of data at speeds far beyond human capability, they lack the adaptability and intuitive problem-solving skills that are inherent to human cognition. Humans, on the other hand, possess the ability to make complex judgments based on contextual information, adapt to unforeseen circumstances, and apply creative solutions to novel problems. The challenge, therefore, lies in designing manufacturing processes that optimally allocate tasks between humans and machines based on their respective strengths.

One area where this symbiosis is particularly evident is in quality control. Automated inspection systems can rapidly scan products for defects with a level of consistency and accuracy that surpasses human capabilities. However, these systems may struggle with nuanced defects or anomalies that deviate from their programmed parameters. In such cases, human inspectors can provide valuable supplementary analysis, applying their experience and contextual understanding to identify and interpret complex defects that might elude automated detection.

Moreover, the implementation of automation does not negate the need for human oversight and decision-making. In fact, it often elevates the role of human operators to that of system managers and strategic decision-makers. These individuals are responsible for interpreting data generated by automated systems, making informed decisions based on this information, and continually optimizing processes. This shift demands a workforce with enhanced analytical skills and a deeper understanding of the manufacturing process as a whole.

The concept of “collaborative robotics” or “cobots” exemplifies this symbiotic approach. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human operators, complementing their skills and enhancing their capabilities. For instance, a cobot might handle the heavy lifting and precise positioning of components, while a human worker performs more delicate assembly tasks that require fine motor skills and judgment. This collaboration not only reduces physical strain on workers but also minimizes errors by allocating tasks to the most suitable “performer,” whether human or machine.

Furthermore, the integration of automation and human expertise facilitates a more comprehensive approach to error prevention and quality assurance. Automated systems can continuously monitor production parameters and collect data on process performance. Human experts can then analyze this data to identify trends, anticipate potential issues, and implement proactive measures to prevent errors before they occur. This predictive approach to error management represents a significant advancement over traditional reactive methods.

However, achieving this optimal balance between human input and automation is not without challenges. It requires a significant investment in both technology and human capital. Organizations must not only acquire and maintain sophisticated automated systems but also invest in training programs to equip their workforce with the skills necessary to operate in this new paradigm. Additionally, there is a need for ongoing research and development to refine the interfaces between human operators and automated systems, ensuring seamless interaction and communication.

As we look to the future, the evolution of artificial intelligence and machine learning promises to further enhance this symbiotic relationship. AI systems capable of learning from experience and adapting to new situations could potentially bridge the gap between the consistency of automation and the adaptability of human cognition. This could lead to manufacturing environments that are not only more error-resistant but also more innovative and responsive to change.

In conclusion, while automation undoubtedly plays a crucial role in reducing human error in manufacturing, its true potential is realized when it is thoughtfully integrated with human expertise. This symbiotic approach not only minimizes errors but also drives innovation, enhances product quality, and creates a more engaging and fulfilling work environment for human operators. As technology continues to advance, maintaining this balance will be crucial in shaping the future of manufacturing.

Questions 21-26

Complete the sentences below.

Choose NO MORE THAN TWO WORDS from the passage for each answer.

- The most effective approach to error reduction involves a __ integration of human expertise and automated systems.

- Unlike automated systems, humans possess __ problem-solving skills.

- In quality control, human inspectors can identify complex defects that might __ automated detection.

- The implementation of automation often elevates human operators to the role of system managers and __.

- Cobots are designed to work __ human operators, complementing their skills.

- The integration of automation and human expertise allows for a __ approach to error prevention.

Questions 27-30

Do the following statements agree with the claims of the writer in the reading passage?

Write

YES if the statement agrees with the claims of the writer

NO if the statement contradicts the claims of the writer

NOT GIVEN if it is impossible to say what the writer thinks about this

- Automated systems are superior to humans in all aspects of manufacturing.

- The implementation of automation requires significant investment in both technology and human capital.

- Collaborative robotics has completely replaced traditional industrial robots in manufacturing.

- The development of AI and machine learning could potentially enhance the symbiotic relationship between humans and automated systems in manufacturing.

Questions 31-35

Choose the correct letter, A, B, C, or D.

-

According to the passage, what is the main advantage of human workers over automated systems?

A) Speed of operation

B) Consistency in repetitive tasks

C) Adaptability and intuitive problem-solving

D) Data processing capabilities -

In the context of quality control, human inspectors are particularly valuable for:

A) Rapid scanning of products

B) Identifying programmed defects

C) Analyzing nuanced or complex defects

D) Replacing automated inspection systems -

The concept of “collaborative robotics” involves:

A) Robots working independently of humans

B) Humans supervising robots from a distance

C) Robots and humans working together complementarily

D) Robots teaching humans new skills -

According to the passage, what is a key challenge in achieving an optimal balance between human input and automation?

A) Resistance from workers

B) High cost of automated systems

C) Lack of suitable technology

D) Investment in both technology and human capital -

The author suggests that the future of manufacturing will likely involve:

A) Complete replacement of human workers by AI

B) A return to traditional manual manufacturing methods

C) Enhanced symbiosis between human expertise and advanced AI systems

D) Decreased importance of error reduction in manufacturing processes

Answer Key

Passage 1

- TRUE

- FALSE

- TRUE

- NOT GIVEN

- TRUE

- repetitive

- real-time

- complex calculations

- painting

- initial

Passage 2

- B

- C

- C

- A

- variability

- error-detection

- fatigue

- data collection

- productivity

- artificial intelligence

Passage 3

- synergistic

- intuitive

- elude

- strategic decision-makers

- alongside

- predictive

- NO

- YES

- NOT GIVEN

- YES

- C

- C

- C

- D

- C

Conclusion

This IELTS Reading practice test on the impact of automation on reducing human error in manufacturing provides a comprehensive overview of the topic while testing various reading skills. By working through these passages and questions, you’ll not only improve your understanding of this important subject but also enhance your ability to tackle different question types in the IELTS Reading exam.

Remember, success in IELTS Reading comes from regular practice and developing effective strategies for each question type. Keep refining your skills, and you’ll be well-prepared for the actual test. For more practice on related topics, check out our articles on how automation is improving workplace safety and the impact of automation on the global economy.

Good luck with your IELTS preparation!